You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Video instructions.

- Thread starter HEISENBERG

- Start date

- Joined

- Aug 16, 2022

- Messages

- 912

- Solutions

- 2

- Reaction score

- 613

- Points

- 93

- Joined

- Jun 24, 2021

- Messages

- 1,729

- Solutions

- 2

- Reaction score

- 2,010

- Points

- 113

- Deals

- 666

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 3,040

- Solutions

- 3

- Reaction score

- 3,463

- Points

- 113

- Deals

- 1

I want to apologize for this mistake to our forum members. Hope you'll like this video. Everything are fixed. Enjoy.

- Joined

- Aug 16, 2022

- Messages

- 912

- Solutions

- 2

- Reaction score

- 613

- Points

- 93

Sick sick sick @G.Patton @HEISENBERG

Thanks so much for your effort.

BTW - is there already progress in the NaBH4/CuCL2 synthesis tutorial for amphetamine?

Thanks so much for your effort.

BTW - is there already progress in the NaBH4/CuCL2 synthesis tutorial for amphetamine?

- Joined

- Aug 16, 2022

- Messages

- 912

- Solutions

- 2

- Reaction score

- 613

- Points

- 93

We need a video of this synthesis method

bbgate.com

bbgate.com

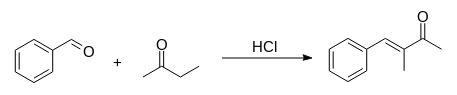

Phenylacetone (P2P) synthesis from benzaldehyde with butanone

Reagents: Benzaldehyde 1000 g; Methyl ethyl ketone (MEK) 1000 ml; Distilled water 14.5 L; Chloroform (CHCl3) 7.6 L; Sodium bicarbonate solution (NaHCO3); Magnesium sulphate (Na2SO4) anhydrous; Glacial acetic acid 10 L; Hydrogen peroxide (H2O2) 1300 g 50 %; Sodium hydroxide (NaOH) 600 g...

bbgate.com

bbgate.com- Joined

- Sep 2, 2022

- Messages

- 42

- Reaction score

- 20

- Points

- 8

We need a video of this synthesis method .

HEISENBERG please

bbgate.com

bbgate.com

HEISENBERG please

Phenylacetone (P2P) synthesis from benzaldehyde with butanone

Reagents: Benzaldehyde 1000 g; Methyl ethyl ketone (MEK) 1000 ml; Distilled water 14.5 L; Chloroform (CHCl3) 7.6 L; Sodium bicarbonate solution (NaHCO3); Magnesium sulphate (Na2SO4) anhydrous; Glacial acetic acid 10 L; Hydrogen peroxide (H2O2) 1300 g 50 %; Sodium hydroxide (NaOH) 600 g...

bbgate.com

bbgate.com- Joined

- Nov 19, 2022

- Messages

- 39

- Reaction score

- 14

- Points

- 8

P2p - we want amphetamine video

bbgate.com

bbgate.com

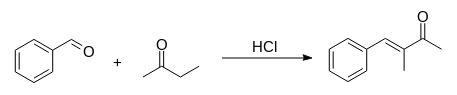

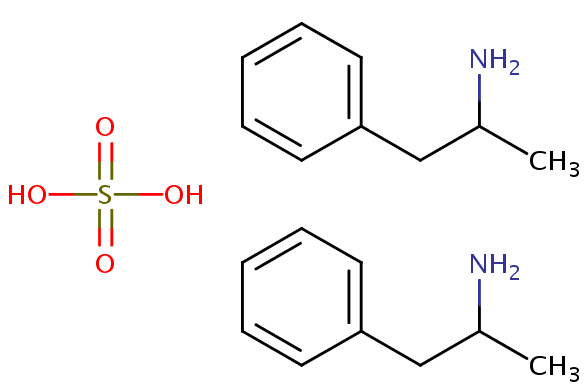

Amphetamine from P2P (phenyl-2-propanone)

Introduction Amphetamine can be obtained in a 30% yield in a one-step synthesis by refluxing phenylacetone in ethanol with ammonia, aluminium grit, and a small quantity of mercuric chloride. By trying out this reaction procedure for amphetamine, it was found that the yield of the reaction was...

bbgate.com

bbgate.com- Joined

- Jun 24, 2021

- Messages

- 1,729

- Solutions

- 2

- Reaction score

- 2,010

- Points

- 113

- Deals

- 666

NEW VIDEO!

- Language

- 🇷🇺

- Joined

- Nov 10, 2022

- Messages

- 76

- Reaction score

- 169

- Points

- 33

Good method, congratulations. Why didn't you choose the method of obtaining amphetamine through 1-phenyl-2-nitropene > 1-phenyl-2-nitropropane > ZINC + hydrochloric acid?

The volumes scale more and the temperature is more stable.

The yield of the final product is much higher

The consumption of NaBH4 during the formation of propane at 0-5 degrees is much less, and the yield of the final propane is higher.

Do you think it's enough to get the amphetamine base in isopropanol without additional fractional distillation?

Do you think that the final product does not contain borates?

The volumes scale more and the temperature is more stable.

The yield of the final product is much higher

The consumption of NaBH4 during the formation of propane at 0-5 degrees is much less, and the yield of the final propane is higher.

Do you think it's enough to get the amphetamine base in isopropanol without additional fractional distillation?

Do you think that the final product does not contain borates?

- Joined

- Jun 12, 2022

- Messages

- 82

- Reaction score

- 34

- Points

- 8

is this the way it is?

5000 ml three-neck, flat-bottomed flasks. placed in an ice bath and placed on a magnetic stirrer. We install a reflux condenser cooled with running water, a dropper with a pressure compensator and a thermometer.

In the flask we put 70 gr. NaBH4 dissolved in a mixture of 300 ml water and 700 ml IPA.

We drop a solution of 108 gr. P2NP in 200 ml. IPA through an addition funnel, at such a rate that the temperature of the reaction mixture does not rise above 5 degrees.

After adding all the propene in the flask, a white slurry with insoluble borates formed in the flask, cool the mixture to 0 degrees and slowly add 300 mL. chilled 85% acetic acid, keeping the temperature in the flask no higher than 3 degrees. When all the acetic acid has been added, the borates should dissolve and the solution should take on a yellowish beige hue.

We fall asleep in a flask with one portion of 270 gr. zinc dust and add 800 ml through the funnel. 38% hydrochloric acid in the amount of about 50-60 ml. in a minute. Then leave the mixture to stir for 2 hours.

The precipitate is additionally filtered by washing it on the filter with 2-3 portions of IPA, 20-30 ml each. the filtrate must be completely transparent. If there are any foreign inclusions, solid particles, filter again.

Add cooled 50% NaOH aqueous solution to the filtrate until a layer of yellowish oil comes to the surface, which will be separated, and the aqueous layer is washed 3-4 times with 100 ml. IPS. Combine the separated oil and alcohol extracts, add 50 gr. finely ground sodium sulfate, cool the mixture below 0 degrees and hold at this temperature for 2-3 hours. Then the mixture is filtered, the precipitate is washed on the filter 1-2 times with 50 ml. anhydrous IPS.

Add 200 ml to the filtrate. anhydrous acetone, put the mixture on a stirrer and add 96% sulfuric acid dropwise until the acidity of the mixture reaches 5.5 - 6. Already during the addition, a precipitate forms, it is necessary to stir the mixture throughout the volume. If mixing is difficult, a little anhydrous acetone can be added.

After reaching the required acidity, the precipitate is filtered, washed on the filter with a small amount of acetone until completely white and dried in air (or batteries) to constant weight. We get 100 + -10 gr. d,l-amphetamine sulfate.

If necessary, solvents can be distilled from the filtrate, the precipitate can be dissolved in 30-50 ml. anhydrous acetone and get another 5-15 g of the substance. However, these residues are quite dirty and will take a long time to wash through the filter, and recrystallization from an ethanol-water system may be necessary to achieve the same purity as the original product.

5000 ml three-neck, flat-bottomed flasks. placed in an ice bath and placed on a magnetic stirrer. We install a reflux condenser cooled with running water, a dropper with a pressure compensator and a thermometer.

In the flask we put 70 gr. NaBH4 dissolved in a mixture of 300 ml water and 700 ml IPA.

We drop a solution of 108 gr. P2NP in 200 ml. IPA through an addition funnel, at such a rate that the temperature of the reaction mixture does not rise above 5 degrees.

After adding all the propene in the flask, a white slurry with insoluble borates formed in the flask, cool the mixture to 0 degrees and slowly add 300 mL. chilled 85% acetic acid, keeping the temperature in the flask no higher than 3 degrees. When all the acetic acid has been added, the borates should dissolve and the solution should take on a yellowish beige hue.

We fall asleep in a flask with one portion of 270 gr. zinc dust and add 800 ml through the funnel. 38% hydrochloric acid in the amount of about 50-60 ml. in a minute. Then leave the mixture to stir for 2 hours.

The precipitate is additionally filtered by washing it on the filter with 2-3 portions of IPA, 20-30 ml each. the filtrate must be completely transparent. If there are any foreign inclusions, solid particles, filter again.

Add cooled 50% NaOH aqueous solution to the filtrate until a layer of yellowish oil comes to the surface, which will be separated, and the aqueous layer is washed 3-4 times with 100 ml. IPS. Combine the separated oil and alcohol extracts, add 50 gr. finely ground sodium sulfate, cool the mixture below 0 degrees and hold at this temperature for 2-3 hours. Then the mixture is filtered, the precipitate is washed on the filter 1-2 times with 50 ml. anhydrous IPS.

Add 200 ml to the filtrate. anhydrous acetone, put the mixture on a stirrer and add 96% sulfuric acid dropwise until the acidity of the mixture reaches 5.5 - 6. Already during the addition, a precipitate forms, it is necessary to stir the mixture throughout the volume. If mixing is difficult, a little anhydrous acetone can be added.

After reaching the required acidity, the precipitate is filtered, washed on the filter with a small amount of acetone until completely white and dried in air (or batteries) to constant weight. We get 100 + -10 gr. d,l-amphetamine sulfate.

If necessary, solvents can be distilled from the filtrate, the precipitate can be dissolved in 30-50 ml. anhydrous acetone and get another 5-15 g of the substance. However, these residues are quite dirty and will take a long time to wash through the filter, and recrystallization from an ethanol-water system may be necessary to achieve the same purity as the original product.

Attachments

- Language

- 🇷🇺

- Joined

- Nov 10, 2022

- Messages

- 76

- Reaction score

- 169

- Points

- 33

Yes, +- this method. The main task in the formation of propane with a large yield.

Also use an overhead stirrer to stir the zinc.

Also use an overhead stirrer to stir the zinc.

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 3,040

- Solutions

- 3

- Reaction score

- 3,463

- Points

- 113

- Deals

- 1

Hi, I think no. Borates aren't dissolved in such organic solvents.

It is the easiest way to carry out synthesis and A/B extraction in case you don't have distillation kit. The best purification option is carry out steam distillation of amphetamine base.

You can write your synthesis way with yields into detached topic, It would be interesting.

It is the easiest way to carry out synthesis and A/B extraction in case you don't have distillation kit. The best purification option is carry out steam distillation of amphetamine base.

You can write your synthesis way with yields into detached topic, It would be interesting.

- Language

- 🇷🇺

- Joined

- Nov 10, 2022

- Messages

- 76

- Reaction score

- 169

- Points

- 33

I am sure that borates are present in the product. To exclude them, after the formation of propane, add several ml of acetic acid to reactor and stir for several hours. In general, if you are chasing a quick amphetamine, then this is not critical.

When I have free time, I will definitely share technologies.

The yield in any case depends very much on the temperature of the reaction... and the yield of the propane itself that you are already recovering for further manipulation.

The process of cleaning the base is a very important part of the process for me.

Having removed all the alcohol, I mix the base with water and acidify the mass with sulfuric acid ... And I wash it with a non-polar solvent. After that, I discard the solvent and alkalize the acidic water to PH 11-12 (NaOH.)

On a separating funnel, I separate the base and extract the water with DCM. I remove the DXM and combine the base, which is fractionally distilled.

A very important process is to have anhydrous alcohol and dry the base from the remaining water.

Neutralization is carried out with concentrated sulfuric acid while cooling. The resulting mass is filtered in a centrifuge and then filled with acetone and stirred, after which it is filtered by a centrifuge.

Why is it important that alcohol and base do not contain water?

The product is soluble in water and losses can be large.

When I have free time, I will definitely share technologies.

The yield in any case depends very much on the temperature of the reaction... and the yield of the propane itself that you are already recovering for further manipulation.

The process of cleaning the base is a very important part of the process for me.

Having removed all the alcohol, I mix the base with water and acidify the mass with sulfuric acid ... And I wash it with a non-polar solvent. After that, I discard the solvent and alkalize the acidic water to PH 11-12 (NaOH.)

On a separating funnel, I separate the base and extract the water with DCM. I remove the DXM and combine the base, which is fractionally distilled.

A very important process is to have anhydrous alcohol and dry the base from the remaining water.

Neutralization is carried out with concentrated sulfuric acid while cooling. The resulting mass is filtered in a centrifuge and then filled with acetone and stirred, after which it is filtered by a centrifuge.

Why is it important that alcohol and base do not contain water?

The product is soluble in water and losses can be large.

Last edited:

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 3,040

- Solutions

- 3

- Reaction score

- 3,463

- Points

- 113

- Deals

- 1

Can you explain your point of view?

You described Amphetamine purification by acid-base extraction. I told about the same.

I'm looking forward to read your post.

You described Amphetamine purification by acid-base extraction. I told about the same.

I'm looking forward to read your post.

- Joined

- May 21, 2022

- Messages

- 229

- Reaction score

- 215

- Points

- 43

- Deals

- 3

About Us

Our team brings together the best specialists from different fields.

We are ready to share our experience, discuss difficult issues and find new solutions.