- Language

- 🇪🇸

- Joined

- Jan 14, 2024

- Messages

- 75

- Reaction score

- 40

- Points

- 18

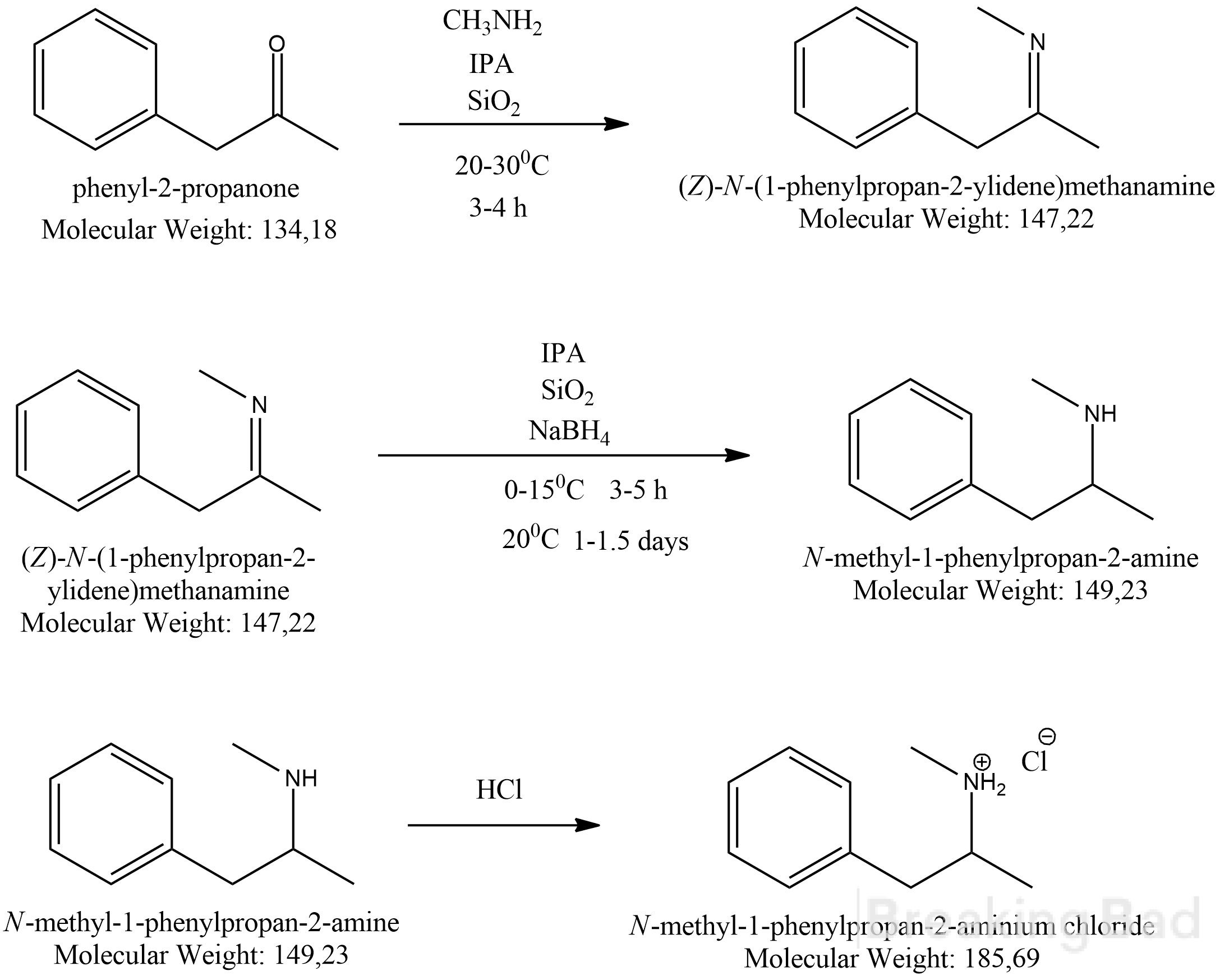

The reactions proceed according to Scheme 1.

Reagents and Materials:

Step 1

Prepare the mixture in the container one day prior to synthesis by combining 20 ml of methylamine, 65 ml of absolute isopropyl alcohol and 15 g of anhydrous sodium sulfate. Add 2-5 g of silica gel to the mixture and periodically stir the mixture with vigorous agitation. Figure 1

Add 40 g of silica gel into a three-necked flask, connect the absorbents (a calcium chloride tube with silica gel and hygroscopic absorbent cotton) and let it stand for 0.5-1 hour to dry. Figure 2

Pour the previously prepared and dried methylamine-in-alcohol solution into the reactor, additionally rinsing the sodium sulfate with portions of isopropyl alcohol. In case the P2P has not been pre-dried, set up a separatory funnel with a layer of silica gel and introduce the P2P into the reactor in portions. After adding all the P2P, rinse the remaining residues with several portions of isopropyl alcohol. Stir the resulting reaction mass for 2 hours, during which the temperature increases from 22 to 30°C, which should be considered for larger synthesis volumes. Figure 3

The next step is to cool the reaction mixture (RM) to 0-5°C. Figure 4

Reagents and Materials:

- 10 g of pure P2P (purified by steam distillation).

- 45-55 g silica gel d=2.5-4 mm (NO powder)

- 3 g sodium borohydride (moles equivalent)

- 65 ml of absolute isopropyl alcohol

- 18.1 - 20 ml 35-40% aqueous methylamine

- 50-100 g of anhydrous sodium sulfate Na2SO4

- 200-250 ml dichloromethane

- 50-100 g of ammonium chloride NH4Cl

- 50 ml of concentrated sulfuric acid (88%)

- 10-15 ml diethyl ether

- 200-300 ml distilled water

- 5-10 g sodium hydroxide

- 500-1000 g ice

- Cold packs

- 1 L three-neck flask

- Distillation set-up

- Vacuum filtration set-up

- Chemical vessels

- Glass adapters

- 2 L separatory funnel

- Heater

Step 1

Prepare the mixture in the container one day prior to synthesis by combining 20 ml of methylamine, 65 ml of absolute isopropyl alcohol and 15 g of anhydrous sodium sulfate. Add 2-5 g of silica gel to the mixture and periodically stir the mixture with vigorous agitation. Figure 1

Add 40 g of silica gel into a three-necked flask, connect the absorbents (a calcium chloride tube with silica gel and hygroscopic absorbent cotton) and let it stand for 0.5-1 hour to dry. Figure 2

Pour the previously prepared and dried methylamine-in-alcohol solution into the reactor, additionally rinsing the sodium sulfate with portions of isopropyl alcohol. In case the P2P has not been pre-dried, set up a separatory funnel with a layer of silica gel and introduce the P2P into the reactor in portions. After adding all the P2P, rinse the remaining residues with several portions of isopropyl alcohol. Stir the resulting reaction mass for 2 hours, during which the temperature increases from 22 to 30°C, which should be considered for larger synthesis volumes. Figure 3

The next step is to cool the reaction mixture (RM) to 0-5°C. Figure 4