GhostChemist

Expert

- Language

- 🇬🇧

- Joined

- Nov 20, 2022

- Messages

- 90

- Reaction score

- 224

- Points

- 33

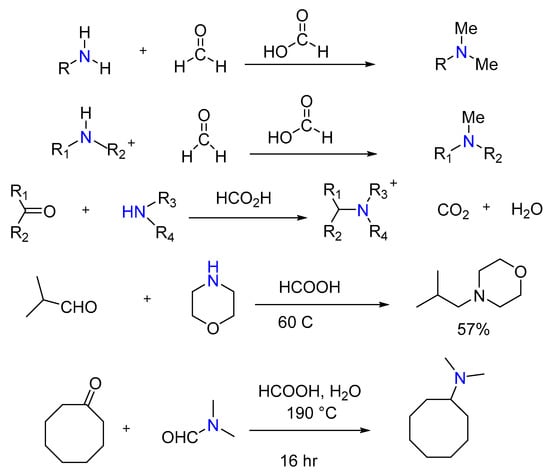

The reactions proceed according to Scheme 1

The initial components are N-methylformamide and P2P. Fig 1

Mixture of N-methylformamide and P2P. Fig 2

The reaction mass reaches a temperature of 160°C. Fig 3

The reaction mass after 1 hour of heating at the specified temperature. Fig 4

The reaction mass, after 18 hours of heating at the specified temperature, turns red. Fig 5

After 36 hours, the reaction mixture is cooled to room temperature. Then, 9.6 grams of sodium hydroxide dissolved in 24 ml of water is added, and the reaction mixture is refluxed for 2 hours with vigorous stirring. There is a significant release of methylamine or ammonia, even upon loading 5 grams!!! Fig 6

After 2 hours of boiling, the reaction mixture is cooled to room temperature and separated into different layers. Fig 7

An aqueous layer is discarded. Hydrochloric acid 32.1 ml (14% aq HCl) or 20 ml 44% sulfuric acid H2SO4 is added to a red organic layer. Fig 8

Methamphetamine is extracted from the aqueous layer with several portions of DCM. Fig 11

The DCM layer is dried with anhydrous sodium sulfate and filtered through a paper filter. Fig 12

DCM is distilled off at a temperature of 90°C. Fig 13

In the flask, there remains a brown oil of the free base with a characteristic amine odor. Fig 14

The obtained free base is dissolved in ethanol and saturated with hydrogen chloride until a strongly acidic reaction is achieved. The color of the solution should also change to raspberry. Fig 15

The resulting solution is evaporated to crystallization. Ultimately, a brown mass is obtained. Fig 16

Subsequently, the mass is fully crystallized. Fig 17

To the obtained crystallized mass, a small volume of diethyl ether is added, and it is transferred to a porous filter. Only one diethyl ether washing doesn't yield a pure product. Fig 18

The final powdery product is the hydrochloride methamphetamine salt. Fig 20

The yield of the hydrochloride (hydrolysis with hydrochloric acid) after washing with diethyl ether and acetone is 2.3 g or 30.8%.

The yield of the hydrochloride (hydrolysis with sulfuric acid) after washing with diethyl ether and acetone is 2.4 g or 32.1%.

When using steam distillation of the free base after the removal of DCM, the yield of the free base is 2.3-2.4 g or 38.3-40%.

Subsequent yield of the hydrochloride is 2.7-2.8 g or 36.2-37.5%.

Reagents and materials:

- 1-Phenyl-2-propanone (P2P) 5.4 ml;

- N-methylformamide 13.4 ml;

- Sodium sulphate (Na2SO4);

- Hydrochloric acid (14% aq HCl) 32.1 ml or 20 ml 44% sulfuric acid H2SO4;

- DCM 100-150 ml;

- Sodium hydroxide (NaOH) 9,6 g in 24 ml H2O;

- Sodium hydroxide (NaOH) 7.5 g in 30 ml H2O;

- Ethanol 88% 10-15 ml;

- Distilled water 100 ml;

- Diethyl ether 5-10 ml;

- Acetone 5-10 ml;

- Hydrogen chloride gas (HCl);

- Flasks;

- Beakers;

- Reflux condenser;

- Hydrogen chloride gas generator;

- Heater;

Execution of synthesis

N-methylformamide is added to P2P, a reflux condenser is attached. The mixture is heated to 165-170°C and refluxed at this temperature for 36 hours.The initial components are N-methylformamide and P2P. Fig 1

Mixture of N-methylformamide and P2P. Fig 2

The reaction mass reaches a temperature of 160°C. Fig 3

The reaction mass after 1 hour of heating at the specified temperature. Fig 4

The reaction mass, after 18 hours of heating at the specified temperature, turns red. Fig 5

After 36 hours, the reaction mixture is cooled to room temperature. Then, 9.6 grams of sodium hydroxide dissolved in 24 ml of water is added, and the reaction mixture is refluxed for 2 hours with vigorous stirring. There is a significant release of methylamine or ammonia, even upon loading 5 grams!!! Fig 6

After 2 hours of boiling, the reaction mixture is cooled to room temperature and separated into different layers. Fig 7

An aqueous layer is discarded. Hydrochloric acid 32.1 ml (14% aq HCl) or 20 ml 44% sulfuric acid H2SO4 is added to a red organic layer. Fig 8

The mixture is boiled under a reflux condenser for 2 hours. After boiling, the color changes to dark green when treated with hydrochloric acid, while it remains brown when treated with sulfuric acid. Fig 9

Then, the solution is cooled to room temperature. The desired aqueous layer is separated, and the organic layer is further washed with water. NaOH solution (7.5 g in water 30 ml) is added. After the addition of the alkali, the color turns brown again. Fig 10

Methamphetamine is extracted from the aqueous layer with several portions of DCM. Fig 11

The DCM layer is dried with anhydrous sodium sulfate and filtered through a paper filter. Fig 12

DCM is distilled off at a temperature of 90°C. Fig 13

In the flask, there remains a brown oil of the free base with a characteristic amine odor. Fig 14

The obtained free base is dissolved in ethanol and saturated with hydrogen chloride until a strongly acidic reaction is achieved. The color of the solution should also change to raspberry. Fig 15

The resulting solution is evaporated to crystallization. Ultimately, a brown mass is obtained. Fig 16

Subsequently, the mass is fully crystallized. Fig 17

To the obtained crystallized mass, a small volume of diethyl ether is added, and it is transferred to a porous filter. Only one diethyl ether washing doesn't yield a pure product. Fig 18

Further washing with even strongly cooled acetone does not yield an absolutely pure product and leads to significant losses due to its high solubility. Fig 19

Due to the fact that the final product is heavily contaminated, despite using initially purified P2P, an analyzing of the obtained data recommends (especially for larger loading volumes of 50 g P2P and more) mandatory steam distillation of the obtained methamphetamine free base after DCM extraction. This will help to avoid significant additional losses. Additionally, based on the conducted experiments, it should be noted that hydrolysis with sulfuric acid is more convenient and prevents its volatilization during boiling, unlike hydrochloric acid.

The yield of the hydrochloride (hydrolysis with hydrochloric acid) after washing with diethyl ether and acetone is 2.3 g or 30.8%.

The yield of the hydrochloride (hydrolysis with sulfuric acid) after washing with diethyl ether and acetone is 2.4 g or 32.1%.

When using steam distillation of the free base after the removal of DCM, the yield of the free base is 2.3-2.4 g or 38.3-40%.

Subsequent yield of the hydrochloride is 2.7-2.8 g or 36.2-37.5%.